Drains

Don’t let sludge glass be a drain on your resources

- use an FIC Drain

FIC, the World’s leading technological innovator, can ensure that melting is not compromised

with a build-up of contaminated sludge glass.

Benefits:

Ensures no glass leakage.

Can include electrode to heat glass above the drainhole more quickly.

Essential, especially for the more difficult, ‘aggressive’ glasses such as opal and borosilicates.

FIC also makes drains for the forehearth.

The regular draining of a furnace to prevent the buildup of inhomogeneous, contaminated glass is essential to avoid the risk of refractory origin cord.

This is especially true of borosilicate, fluoride opal and other of the more ‘aggressive’ glasses.

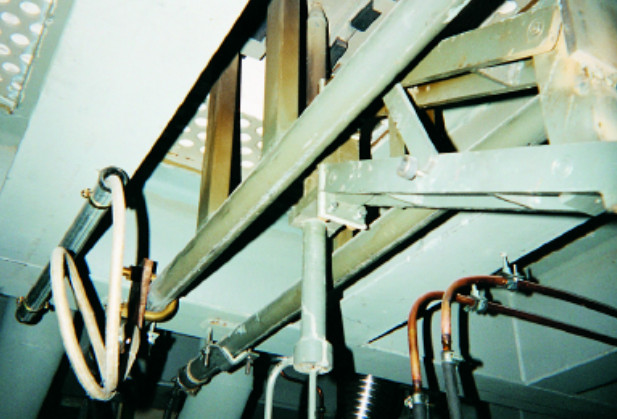

The drain consists of a hole drilled in the furnace bottom and a water cooled framework which allows a burner flame to heat the plug of cold glass to facilitate glass flow and hence removal of build-up of contaminated glass. It can also include a small counter electrode to heat the glass above the hole more quickly by the application of Joulean heat.

A similar system is available for forehearth draining.

Further Information:

-

Please contact us to receive more information, our latest presentation, or a quotation to purchase.