Isothermal Unit

Glass conditioning is the heart of glass making

- the FIC Iso-Thermal Unit

It has long been recognised in the glass industry that Thermal Homogeneity and the means of achieving this goal are crucial to good quality production and maximizing capacity.

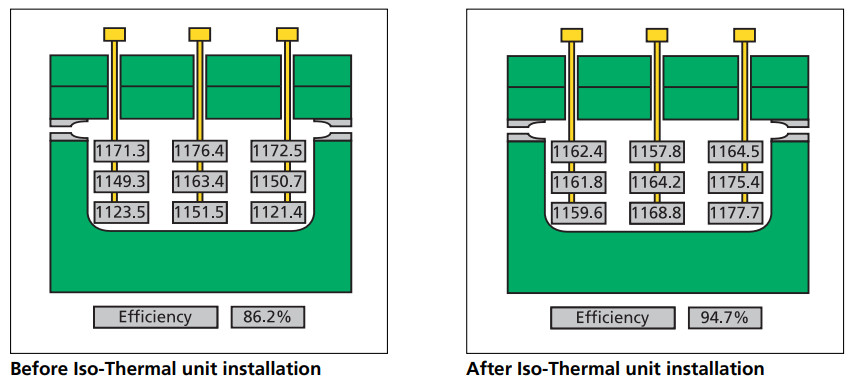

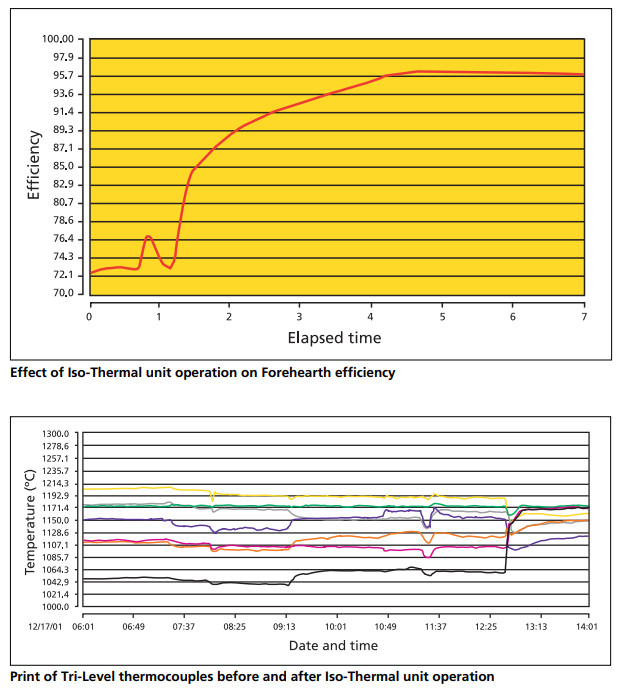

The FIC Iso-Thermal Unit ensures an increased thermal efficiency in the forehearth and consequent homogeneity in the gob.

Small capital outlay

Thermal homogeneity results in more uniform gob weight and improved mass distribution within the article.

Payback: 3-6 months on capital investment

Better gob

= Better loading

= Less swabbing by the operator

= Less equipment changes

= Less damage of the equipment and therefore longer mould life through less cleaning

Benefits:

Particularly beneficial for the more difficult glasses such as coloured, borosilicate and opal glasses.

Faster response to job changes, reflected in increased yield.

Improved flexibility between adjacent forehearths for a constant working end temperature.

Incorporates ‘greatest wins’ secondary current feedback signals which limits the circuit current on individual electrodes to safe, re-adjusted values.

Our electrode-boost design for the forehearth is wellproven not to produce galvanic re-boil.

The FIC Iso-Thermal Unit is an extremely efficient forehearth boosting system which can dramatically improve the thermal efficiency of the forehearth in conventional fuel-fired forehearths.

The system can be easily and quickly installed on existing forehearths during a job change, with minimal disruption to production, or on new forehearths.

The most striking thermal efficiency improvements are made on those glasses inhibiting heat transfer by radiation: dark green or amber glass, multi-gob operation, lightweight containers, NNPB processes, borosilicates and fluoride opal.

The complete unit comprises three main items:

- Power module (usually two 20 kVA transformers)

- Control cubicle

- Set of electrodes (usually eight pieces)

Based on the preferential dissipation of Joulean heat in the colder glass areas adjacent to the channel sidewalls, thus reducing the centre-edge temperature gradients inherent in fuelfired systems, the design has proven to be extremely successful over the life of the furnace and beyond.

The resultant increase in temperature of a greater percentage of the forehearth glass stream improves the heat transfer to remaining areas of lower temperature e.g. bottom glass.

Whilst the electrode configuration employed depends to some extent on the forehearth geometry, pull and glass type, it is usual to employ 8 molybdenum electrodes, 4 per side, in the last 1 to 1.5 metres of the conditioning section. This system can also be used on tandem type forehearths.

Electrode diameter and immersion are specified in accordance with the final design, great care being taken to comply with current density limitations implied by glass type and composition.

The electrodes used are of a proprietary bi-metallic or trimetallic type, either naturally air-cooled or water-cooled according to the forehearth temperature and client preference.

Further Information:

-

-

Please contact us to receive more information, our latest presentation, or a quotation to purchase.